Components in contact with the product

In case of a production change, you can continue to use your multihead weigher. All you need to do is replace the elements that come into contact with the product. Turning a scale initially used for dry applications into one for sticky products or mixtures is quick and easy.

Product touching parts

In the area of product-touching components, we categorize all machine parts whose surfaces come into direct contact with the product. This includes all of the following:

- Infeed funnels

- Infeed rings

- Top cones

- Linear feeder pans

- Feed buckets

- Weigh buckets

- Memory buckets (for memory weighers)

- Collating funnels

- Discharge gates

A wide range of designs

The nature of the surfaces for components in contact with the product is diverse and covers all possible applications. The following are available, among others:

- Plain plate for free-flowing, simple products

- Standard dimple plate for slightly adhesive products

- Yamato dimple plate® for highly adhesive products

- Wire mesh for extremely adhesive products

- PTFE coating (SilverStone, Teflon, etc.) for special adhesive products

Exchange after irreparable damage

The reasons for replacing components in contact with the product can be manifold. Among others, these parts are often damaged throughout the course of operation. This is mostly due to improper handling, e.g. during regular cleaning. Incidentally, training for operating personnel can massively reduce this damage. Learn more about this here.

Exchange after product change

Replacing components that come into contact with the product also gives you the opportunity to change the field of application of an already purchased multihead weigher. For example, if a machine was designed to weigh and package dry and “simpler” products, it can be easily converted and used for sticky products. This means that the components in contact with the product can be selected with a different surface.

Combinations of surface finishes

Any number of combinations of surface finishes is also possible. A weigher originally designed for mono-product can for example be used for mixtures of products with different properties. With this option, the use of a multihead weigher provides you with high flexibility and an unbeatable economic advantage.

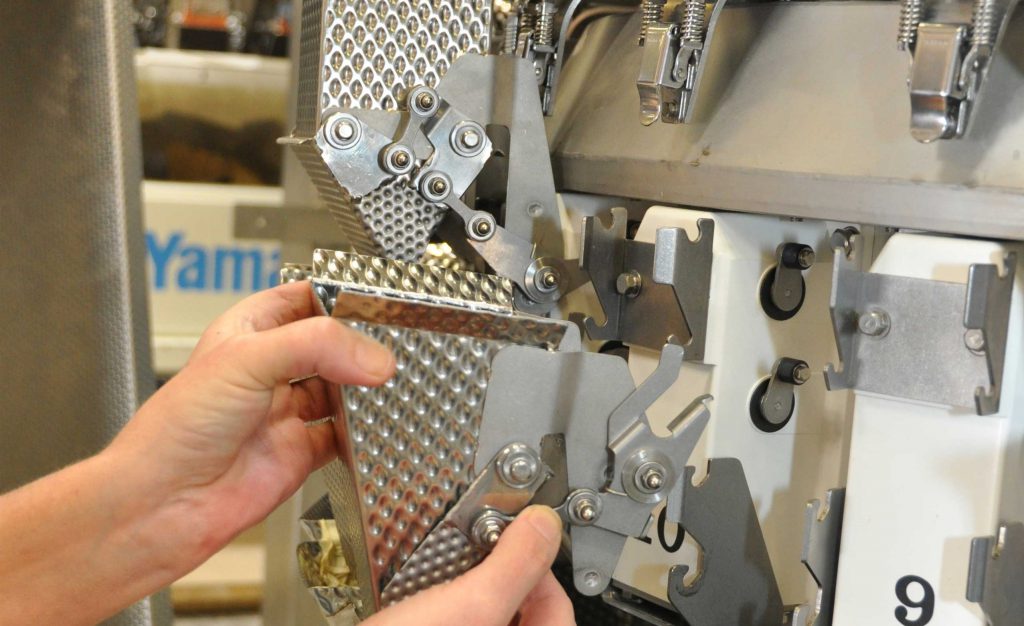

Top cone in the Yamato dimple plate® version

Top cone in the Yamato dimple plate® version. These surfaces are suitable for weighing and packaging smooth, highly adhesive products. A complete set for the entire multihead weigher or else individual parts can be replaced as required. A single product contact part can itself also be made of different surfaces, for e.g. in the picture above, the linear feed pan is made of both Yamato dimple and standard dimple 6WL.

Weigh bucket in a version with Teflon coating

Weigh bucket in a version with Teflon coating. Surfaces with a PTFE (polytetrafluoroethylene) surface are suitable for weighing and packaging highly adhesive products. A complete set with all parts in contact with the product or individual components can be converted from a standard multihead weigher into a machine for packaging cheese, for example.

Feed bucket with design in wire mesh

Feed bucket with a design made of two different materials. The walls of the bucket are made of standard dimple plate, while the doors are made of wire mesh. This design is especially suitable for the weighing and packaging of highly adhesive products such as oiled fruit gums or dried fruits such as soft apricots and plums. A partial application of special surfaces is often an economically viable solution.

Patrick Coursier

Manager Technical/Customer Service

„We are constantly looking for new ways to make the application of Yamato multihead weighers more flexible and profitable for our customers. Many customers change their production or expand their product range and suddenly need a new machine. At this point, we simply recommend replacing the components that come into contact with the product. For this purpose, new operating programs are activated or a software extension is recommended. Our customers appreciate our fair conduct because besides saving them money, the proposed solution also makes a decisive contribution to protecting the environment.”

These recommendations are based on 30 years of experience at Yamato Scale.

YAMATO SCALE Benelux

Edisonstraat 2

5051 DS Goirle

The Netherlands

Country Manager: Walter ten Bruggencate

E-Mail: ysb@yamatoscale.com

Hotline: +31 (0)13 220 11 17

Topics in this article

Product contact parts, feed buckets, weigh buckets, multihead weighers, multihead weighers, multihead scales, automatic multihead equipment, automatic dataweigh, computer combination weighers, industrial weighers, dynamic weighing systems